Small Scale Gummy Making Machine: The Complete Buying Guide

Small Scale Gummy Making Machine is a common food equipment using to produce different batch size of chewy candy. and now, this traditional machine is undergoing a new opportunity! it can be used to produce not only traditional sweets to satisfy people’s appetite, but also different kind of healthier food into the gummy format such as vitamins, minerals, supplement product etc.

Whatever you are a nutraceutical or pharmaceutical company. gummy production line as a new project to your business, knowing the things of it by this guide is helpful for you to take a correct choice.

KOSBEST glad you are here, to help you build your first gummy production line for catch this new booming market !

> Type of Gummy Bear Making Machine in Market

> Support Equipment for Gummy Manufacturing Process

> Choosing Correct Gummy Making Machine for Different Batch Size on Mass Production

> Types of Small Batch Production of Gummy Making Machine

> Specifications of Small Scale Gummy Making Equipment

> Main Parts of Small Scale Gummy Making Machine

> Working Principle of Small Scale Gummy Making Equipment

> Advantages of Small Scale Gummy Making Machine

> Disadvantages of Small Scale Gummy Making Machine

> Different Between Gummy Making Machine and Gummy Candy Maker

> History of the Gummy Bear Manufacturing Process

> Key Ingredients of Gummy Candy

> How to Troubleshoot a Small Scale Gummy Making Machine

> How to Maintain Small Scale Gummy Making Equipment

> How Much Cost of Small Scale Gummy Making Machine

> Know More Trends in Gummy Candy Market

> Which Industries are Using Commercial Gummy Making Machines

Type of Gummy Bear Making Machine in Market

Gummy bear making machine are different from starch mogul machine. the former is used to produce starchless gummy candy, the latter is the opposite. gummy making machine can be divided into the following types according to product capacity and automation:

By Product Capacity

- Small-scale (entry level)

- Medium-scale

- Large-scale

- Ultra-scale

By Automation

- Semi-automatic

- Full-automatic

Support Equipment for Gummy Manufacturing Process

The gummy making equipment goes through multiple processes to compelte the gummy manufacturing, typically requires following machines to support the work.

Jacket Cooker

This jacket cooker is used to prepare the syrup. different batch size requires different volume tank.

Make sure not to overcook at once, it will affect the freshness and quality of end product due to the deposition of syrup at the bottom of the tank for too long.

Storage Tank

This machine is used for a transitional stage. it helps to keep the temperature and fluidity of the boiled syrup by heating and stirring before next stage of depositing.

Transfer Pumps and Pipes

They are used to auto transfer the syrup from cooker to storage tank, then to depositor.

For bigger scale gummy candy production, we suggest to equip double layers pipe to delivery the syrup, by way of hot water circulation inside the jacket to keep warm and fluidity of syrup without problem of clogged up on the way.

CFA Mixer

It comes to add the colors and flavors stage. there are two options of CFA mixer for small and big scale gummy production:

Dynamic mixer and static mixer

One is an inline mixer for small capacity, one is a high-efficiency metering pump for precise dosing and blending of colors and flavors.

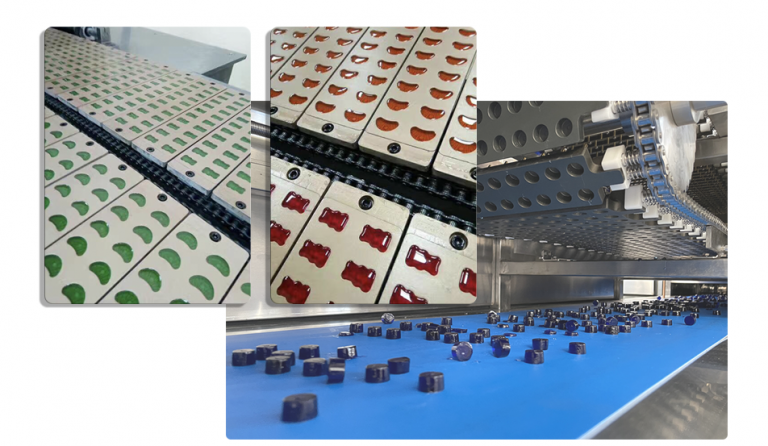

Depositing Machine

It is a big part in gummy manufacturing. in here, the syrup completes the injection/feeding action from the hopper into the molds by precise amount according your setting.

Cooling Tunnel

The cooling tunnel is used for gummy cooling stage, it often connects with depositing machine to finish some continous actions.

The steps following:

The syrup auto inject into the molds by depositor, then go through to cooling tunnel for quick cool down and forming. finally get release from the depositing machine.

Other Optional Auxiliary Machines

Base on your gummy style requirement, you might need other auxiliary machines for additional process of gummy manufacturing:

Wax polishing pan

Sugar sanding drum

Choosing Correct Gummy Making Machine for Different Batch Size on Mass Production

To know what machine is suitable to you, a professional gummy making machine supplier will give you a best suggestion. But before that, thinking of what you want is first important thing you need to consider.

Type of Guumy

What gel materials you use and how many color in a gummy candy you want to make.

Generally there are 1-2 colors for choice. Pectin powder more friendly for the vegetarian.

Machine’s Dimension

Check how much area of the workshop do you plan to use for gummy production.

The Bigger production capacity, the bigger demension of gummy production line.

Production Capacity

Considering what batch size you want per hour. it directly affects the choice of optional machine type.

In this case, small scale gummy production line have more options between semi-auto and full-auto machine. a larger scale gummy production line will need a full automatic machine.

Cost of Machine

Know about your product’s profit margin and target market size. according your budget to get an afforable and suitable gummy making machine.

Maintenance Costs

Choosing an easy-clean gummy making machine with high quality gummy molds and the structure of easier disassemble wearing parts’s design for getting a long-life using and saving money.

Types of Small Batch Production of Gummy Making Machine

There are mainly semi-auto and full automatic small scale gummy making machine in market.

Most customers choosing a small scale gummy making equipment as a pilot machine for starting their gummy manufacturing at first. it helps you obtain pilot results that can be extrapolated for future larger scale production.

Usually we define a small scale production when its batch size less than 80kg/h.

Specifications of Small Scale Gummy Making Equipment

It is an important part that let you know what things you need to focus on and related to your production closely.

The Dimensions of Machine

The production capacity of a gummy machine is proportional to its dimension.

In other words, your workshop’s size may also determines your machine’s size.

Batch Size Requirement

The batch size of your production is an important indicator that deciding the specification of your whole machine and depositing system.

Therefore, you have to ensure that you don’t give a wrong number to your suppliers.

Power Source Requirment

There are two power ways between electric and steam for you choosing. the steam one is more efficient than electric one, but it requires your factory has steam support!!

About voltage, different level of small scale gummy making machine requires different power support. in addition, three phase power supply better accommodates higher loads more than single phase, it is a better option or the only one choice for most gummy machine model.

So, Ensure your factory’s power match the machine requirement!

Pneumatic Requirements

This is a pressure-related indicator.

Since some works of a gummy making machine through air pressure to perform, it has a pneumatic system to assist.

The pneumatic system is used to produce air pressure and controlling its amount according to the working configurations of the machine.

You should pay attention to some important pressure or penumatic requirement for better machine operation.

- Compressed air consumption

- Compressed air pressure

- Steam consumption

- Steam pressure range

Operational Conditions Requirement

Remember to check and meet the other requirements of what temperature, humidity and so on conditions are needed to your machine.

For food manufacturing, a good operational conditions of your workshop is good for producing good products.

Main Parts of Small Scale Gummy Making Machine

A complete gummy manufacturing process requires different parts to assist in process. which parts are needed depend on different machine design and working requirement.

As earlier mentioned, small scale gummy making machine has semi-auto and full-automatic for option.

Necessary Parts

- Mixing System

- Heating System

- Depositing System

- De-moulding System

Optional Parts

- Transfer system

- Depositing System

- Dosing System

- Oil Spray System

- Cooling System

- Mores

Working Principle of Small Scale Gummy Making Equipment

Small scale gummy making equipment working principle is base on the flow of gummy process.

The basic process of a full automatic small scale gummy making equipment follows the steps through syrup cooking, syrup store, colors and flavors adding and mixing, depositing, cooling and forming.

Steps:

First, put the prepared materials in place of jacket cooker for heating and mixing. when it boils and mixing well, the syrup is automatic delivered to the storage tank through a transfer pump for temporary store in a warm and stirring conditions.

Next it is automatic driven by a lobe pump to be in an inline mixer or a dosing pump for adding colors and flavors to mix with it.

After mixing well, then the mixed syrup is automatic transferred into the hopper of depositing machine for completing the injection action. in here, the syrup is controlled by a servo motor to be injected into gummy molds with an accurate amount of each.

Last, the liquid syup in the mold is driven by the conveyor belt of depositing machine go accross the cooling tunnel for getting a quickly cool down and forming. then finally get release from the mold by depositing machine.

Advantages of Small Scale Gummy Making Machine

The greatest benefit of a small scale gummy making machine is that it offers an accurate dosing system and more flexible configuration capabilities for match your diverse production requirement.

Of course, its benefits are not limited to these. you can also have a good experience on below benifts, but some of them deponds on what level of automation you want.

• Small footprint design available.

• Easy operation by using touch screen to control the production.

• Only requires a less labor on operation of production.

• Whole machine can be set up in a modular design. Easy assemble and disassemble.

• Easy clean design. allows you clean it by turn on the machine and using a same way which you using to produce gummy. just using water and cleaning agent instead of the materials of your gummy recipe. also the parts are removable for clean.

• Lower maintenance cost, which you may only required on clean work and regular lubrication.

• High quality gummy mold for long-term using.

• High quality lectrical components from internationally-known manufacturers.

• Contact parts made of food grade stainless steel.

Disadvantages of Small Scale Gummy Making Machine

Even if small scale gummy making machine has plenty benefit, it also has some defects.

♦ The price in the market is little higher, due to they are produced according to high standard manufacturing requirements.

♦ You might need to pay an extra charge for get a installation service.

Different Between Gummy Making Machine and Gummy Candy Maker

Gummy making machine is an commercial equipment that using for the mass production of gummy candy by the manufacturers. Gummy candy maker is just a very small DIY kitchen product which is used to make a homemade gummies food for a personal use.

History of the Gummy Bear Manufacturing Process

The process of manufacturing gummy bears is one that’s been in practice since the 1920s when the first gummy candy was invented by a German candy maker named Hans Riegel. the delicious chewy candies have since become a staple in the candy industry, and are enjoyed by children and adults alike.

This process has remained fairly consistent over time, but with one major change: mass production! Gummy bear molds are now much larger than they once were, producing thousands of little bears at a time.

Key Ingredients of Gummy Candy?

Gummy candy is a type of gelatin-based sweet that has a chewy, jelly-like consistency. Gummy candies are typically made using gelatin, sucrose, starch, and water. The candy is shaped into whatever form is desired, and then allowed to dry for several days so that it will retain its shape.

These ingredients are combined and then poured into molds that take on their distinctive bear shape. After cooling, they are removed from their molds and packaged for sale.

Gelatin is the primary ingredient in gummy candy because it gives the candy its jelly-like consistency. Gelatin was originally used for medical purposes. In fact, the term “jello” comes from the word “gelatin.” Today, it’s also used in candy making to give the candy a soft and chewy texture, as well as to help stabilize some ice creams and yogurts. Gelatin is made from proteins found in animal bones and tissues, and it is produced by boiling these tissues in water until they dissolve. The resulting solution is then purified, filtered, and dried into a powder that can be mixed with other ingredients to make gummy candy.

Sucrose is another key ingredient in gummy candy because it provides a sweet flavor; however, sucrose also serves as an anti-caking agent for gelatin. Dextrose is sometimes used instead of sucrose or along with sucrose to help provide sweetness and preserve the gelatin. Starch or pectin may be added as thickeners to improve the texture of the final product. Water binds all of these ingredients together and allows them to solidify when cooled. Natural or artificial flavors are often added to gummy candies.

Fruit juice or puree can be added for flavor, and food coloring is often used to make gummy candies colorful. Sometimes citric acid is added to give tartness; other acids such as malic acid (as found in fruit) may also be used if producing sour-flavored gummies.

Starch is used in gummy candy as a bulking agent and a thickening agent. Starch comes from a variety of different sources, such as corn, wheat, and potatoes. The starch can be combined with gelatin to produce the base for gummy candy.

Water is added to the formula to help dissolve the sugar and other ingredients in the candy. Sugar is added as a sweetener as well as a preservative – it prevents bacteria growth, which allows the candy to be stored for long periods.

How to Troubleshoot a Small-Scale Gummy Making Machine

Just like any other machine, a gummy candy-making machine can develop problems. Luckily, many of these issues are simple to troubleshoot. Below is a list of common problems you may encounter when using your gummy-making machine.

The gummy candy-making machine is not working properly-If the machine is not working properly, double-check that it is plugged in and turned on. If the power light does not turn on when the power switch is flipped on, there may be a problem with the power supply cord.

If your gummy-making machine is plugged in but still not turning on then there might be a problem with the fuse of your machine. You need to replace the fuse with a new one if you want to restart your machine.

If the power of your gummy-making machine is on but it’s not operating properly then there might be a problem with its motor or gearbox assembly. If you want to fix this problem then you need to replace both of them with new ones as

The gummy candy-making machine has stopped working-First, check to make sure the gummy candy-making machine has not overheated. If it has been running for more than an hour straight, or if it is particularly hot outside, then take a few moments to let it cool down before trying again. If the gummy candy-making machine has not overheated, and still will not work after letting it sit for several minutes, then there may be an issue with the motor or gear system. Try oiling the gears and rotating them manually to see if they move freely. If they do not move easily or smoothly, then you will need to replace them.

How to Maintain a Small Scale Gummy Making Machine

When it comes to maintaining small-scale gummy-making machines, there are many different options available on the market. Many manufacturers offer different styles of machines that are designed to be used for various types of production processes.

Some machines are designed for large-scale production while others are designed for smaller-scale production. In order to make sure that your machine can handle whatever you need it to do, it is important that you take the time to find out about each type of machine that you are interested in purchasing. This will allow you to get a better idea as to what type of machine will best meet your needs.

There are several other considerations that you should take into consideration when purchasing a machine for gummy making. One consideration is the amount of money that you want to spend on your machine. This includes both the price and maintenance costs associated.

Here are some ways to maintain the small-scale gummy making machine:

1. Keep Changing the Oils

You need to change the oils of the machine regularly, especially when they have been used for a long time. This prevents dirt from accumulating on the machines and makes them last longer than usual.

2. Cleaning the Machine Regularly

Another way to maintain is by cleaning it regularly with a cloth so that there is no dust or dirt on its surface which could cause damage later on.

3. Checking the Machinery Parts

In this step, one should check all parts of the machine carefully. If any part is broken, then it should be replaced immediately.

4. Maintenance Schedule

Gummy Making Machine needs regular maintenance for its smooth functioning. So, one should create a maintenance schedule and follow it strictly on daily basis without fail.

5. During use, keep an eye on whether there are unusual noises or malfunctions in the machine and whether there are loose screws or leaking oil in each part of the equipment to ensure safety and reduce damage to equipment.

6. After using the small-scale gummy making machine, close all valves, clean up all areas of use and grease, then turn off the power supply and close all doors to prevent dust from entering and affecting normal operation next time you use it.

7. When starting up again, remember to check whether all parts are in good condition and that each part is working properly before starting production.

How Much Cost of Small Scale Gummy Making Machine

Small scale gummy making machine price during 15,000usd to 180,000usd in market, the finally price mainly depends on below factors:

- Production capacity

- Automation level

- Origin

- Quality of processing material

Know More Trends in Gummy Candy Market

Gummy candies are experiencing explosive growth in the U.S., Canada, and Europe. The market is expected to grow at a compound annual growth rate (CAGR) of over 6% from 2018 to 2023. This is largely due to the rising demand for healthier products with natural ingredients, as well as the rising trend of gummies being used for medicinal purposes.

In the U.S., the market has been growing at a CAGR of more than 6% since 2016 and is expected to continue its upward trajectory until 2023. Most of this growth is driven by customer demand for gummies that are free of chemicals and artificial sweeteners, such as corn syrup.

Gummy candies are seeing a real resurgence in popularity, and the industry is responding by bringing out new flavors, shapes, and textures in order to cash in on this opportunity.

Natural ingredients have become more popular, as consumers seek out healthier options for their children, and for themselves. Organic is also a big trend in the gummy candy market, as consumers feel that organic ingredients are better for their health. Organic sugar has even become more popular than traditional sugar. Gummy candies are also becoming more colorful, with many brands using vegetable dyes to make them look more enticing.

While these trends may be good news for consumers who want to eat healthier gummy candies, they could spell trouble for traditional manufacturers who don’t adapt to changing consumer tastes and preferences. They may need to start looking at developing their own range of natural, organic gummies if they want to remain competitive in this market.

Which Industries are Using Commercial Gummy Making Machines

Gummy-making machines are becoming increasingly popular in many different industries. For example, the food and candy industries have long used gummy-making machines to create a wide variety of fun shapes and sizes in their products. But recently, pharmaceutical and cosmetic companies have started using these machines to manufacture gummies as well.

Because gummy-making machines are highly customizable and easy to use, they can be adapted for different purposes with relative ease. These new uses for gummy-making machines allow them to serve an even wider variety of purposes than before.

Many industries are using commercial gummy-making machines. Some of the most popular industries include:

Food Industry

The food industry is one of the biggest industries that use gummy-making machines. Commercial gummy-making machines are used in the food industry to create gummies for human consumption. This can include gummies for kids, adults, and pets. Gummies can be used as a food product or added to a food product to enhance their texture, flavor, or nutritional value. There is also a growing demand for gummies as a healthy alternative to other snack foods.

Nutraceutical Industry

Gummies are also used in the pharmaceutical industry. This is because they are popular with people who do not like to swallow pills. For example, many medication companies are now using commercially made gummies to deliver vitamins and other medications to patients who cannot swallow pills. Gummies are great for children and adults that have difficulty swallowing pills, as they dissolve quickly and taste great.

One-Stop Solution Manufacturer of Gummy Making Machine

One-Stop Solution Manufacturer of Gummy Making Machine