KOSBEST®️ CBD Gummy Bear Machine

KOSBEST Ltd is a Chinese factory for food processing equipment based in ZhuHai, we mainly focus on the production line equipment and technologies of the Gummy Bear Machine.

With over 10 years experience in helping to built gummy bear machine for foreign factories, our gummy production line equipment is also constantly improving and upgrading. From processing materials, electrical configuration, adaptability of manufacturing system, control system integration, then to the improvement of the details, all of these help us get more trust from our clients.

CBD Gummy Candy Trends

Recent years, the rise of CBD gummies in North America has given us a greater breakthrough in the manufacturing experience and technology of gummy industry. many foreign health food factories and contract manufacturer have built their own gummy production lines from us under this trend. according to relevant agency reports, the CBD gummy market is growing, with a current estimated value of $4.3 billion, and is projected to grow to $7.9 billion by 2022.

Get Start to Built your First CBD Gummy Production Line from KOSBEST®️

We offering online technical support, formula support, CBD market insights and high quality whole line of gummy bear machine. Get in touch with us!

Factory Acceptance Testing Video of Gummy Bear Machine

What are CBD Gummies

CBD gummies are soft chewable candy that contains compound CBD which an extract of the hemp plant.

Just like the various nutritional supplements that vitamin gummies can bring to the human body, eating CBD gummy bears can also bring many benefits to people. in addition to helping relieve mental depression and anxiety, it can also reduce physical pain of the human body. for this reason, it usually marketed for adults and seniors.

How to Make CBD Gummies by Gummy Bear Machine

To manufacture high-quality CBD gummy candy, a good gummy candy machine is the most basic requirement. KOSBEST CBD gummy bear machine is such a machine, which provides a one-stop service from raw material pretreatment to cooling and forming processed.

In the CBD gummy candy manufacturing process, the different choice of formula and the selection of gel powder make your end products have different taste and chewiness. gelatin and pectin are currently the most used raw materials for gel powder in gummy candy industry. they have a similar gel effect, but due to gelatin based from animals and pectin comes from plant, so a pectin gummy candy is best choice for a vegan. the recipe of CBD gummies also different from different manufacturer, but basically they contain sugar, fruity flavors, citric acid, and of course CBD oil.

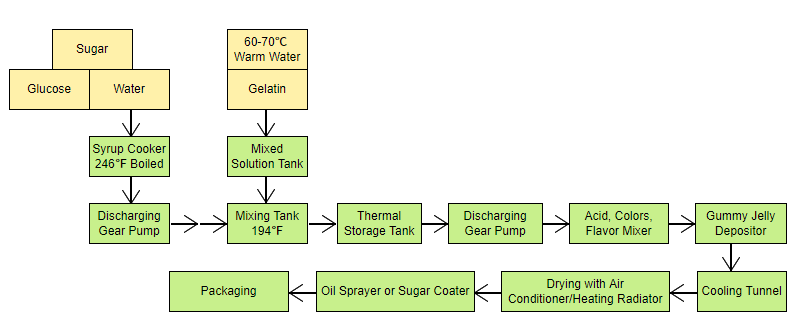

The basic process and making machine of CBD gummies are same as other ordinary gummies, just a CBD-containing extract added to the formula. a typical manufacturing process would be as follows:

KOSBEST®️ CBD Gummy bear Machine

Why KOSBEST®️ CBD Gummy Bear Machine

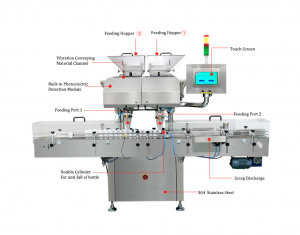

KOSBEST Gummy Bear Machine is a powerful gummy candy production line can help you produce tens of thousands of CBD gummies in a short period. the design is based on the flow production of the CBD gummies manufacturing process. built with high quality, intelligence, modularity, precise output control system, easy disassembly and assembly structure etc features. the details as follows:

- The main processing material uses 304 and 316 stainless steel which reduces chances of contamination.

- UL and CSA electrical safety standard which ensure your production is under the safe environment.

- PLC control system and HMI system allow you by easy way to control and set up the machine and production

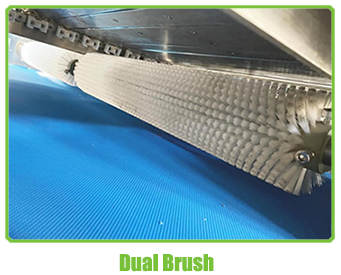

- Quick release gummy molds design with dual brush which ensure your continuous production getting smoothly without build up of gummies.

- Two dosing systems allow you to make single or double colors of gummies.

- Dosing pump can accurately control the flow rate and dosing of materials, ensure the ingredients of the end product are exactly according to your settings.

- Oil spraying system on the depositing machine for giving the smooth surface of gummy molds and make easier release of gummies.

- Easy cleaning way by directly using water or other cleaning agent.

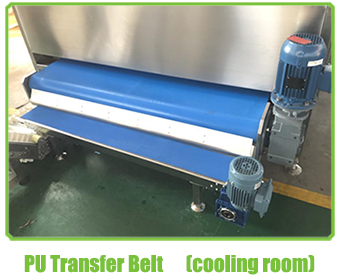

- Modular design of whole machine line, allow you to easily assemble and disassemble the machine like stacking blocks.

One-Stop Solution Manufacturer of Gummy Making Machine

One-Stop Solution Manufacturer of Gummy Making Machine