Carrageenan: The Ideal Gelatin Replacement in Vegan Gummy Candy

What Exactly is Gummy Candy

Gummies, gummy candies, or jelly candies are a variety of chewy treats made of gelatin. In the confectionery sector, jelly babies and gummy bears are well-known and extremely popular products. Gummies come in a wide range of shapes, but the most popular ones are vivid representations of living things like bears, newborns, or worms. For example, Bassett’s, Haribo, Betty Crocker, Disney, and Kellogg’s all produce different kinds of gummy snacks that are frequently marketed to young children. While the term “jelly” is more frequently used in British English, the name “gummi” is Germanic in origin.

What Exactly are Vegan Gummy Candies

No matter what kind of dietary restrictions a person has, they can still enjoy delectable vegan gummy candies.

Vegan gummy candies don’t contain any animal products while being created using plant-based materials. As a result, vegans don’t have to worry about consuming any additives that might contradict their dietary principles while enjoying these delectable sweets.

Because vegan gummy candies are manufactured from plants rather than using meat or dairy from animals, vegetarians can also enjoy them. In other words, vegetarians can enjoy this candy without worrying about ingesting anything that came from an animal, such as eggs or milk, which could conflict with their dietary principles or make them uncomfortable while eating specific dishes.

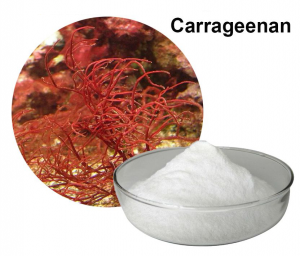

What is Carrageenan

Carrageenan’s coagulability, solubility, alkalinity, and other properties make it useful as a thickening, coagulant, suspending agent, emulsifier, and stabilizer. It is used in a variety of ways in the food industry and other sectors.

In China, carrageenan has a long history of use in the production of soft jelly candies. It is particularly well-liked by customers since it has a potent fruit flavor, is refreshing and non-sticky, and is just moderately sweet.

It can be used to create standard fruit jelly candies, premium fruit jelly candies by including nutrients, or nourishing jelly sweets by including nutritious ingredients.

Ingredients for Vegan Gummi Candy

White granulated sugar and syrup serve as the primary raw ingredients for carrageenan jelly candy, which is then flavored and colored in addition to using carrageenan as a gelling agent.

Classifications

According to flavor and appearance, carrageenan vegan chewy gummy sweets are divided into the following categories:

Gummy Candy with Carrageenan in It

It is possible to create both transparent and opaque soft candies, and the flavor is not sticky. The starch-based opacifiers, including maize sugar, are typically added to the elastic and opaque soft candies.

Carrageenan Gummy Candy with Acid

To create sweet and sour soft candies with the same taste and better flavor, a sour agent is applied when creating soft candies.

Pouring Gummy Candy

Pour the material into the mold and shape it all at once using a pouring machine. This soft candy is instantly heated to the proper wetness without drying, giving it a chewier flavor and a brighter, more clear surface.

In addition to these, chewy gummy sweets may also contain gelatin, agar, pectin, modified starch, etc. Each has distinctive qualities and diverse tastes.

How to Make Candy That Is Vegan

Recipe for Vegan Gummi Candy

- General Carrageenan Jelly Candy Ingredients:

35 kg of water

1.2 kg of compound carrageenan powder

60 kg Syrup

40 kg White Sugar

- Acidic carrageenan jelly candy ingredients:

35 kg of water

1.4 kg of compound carrageenan powder

60 kg Syrup

40 kg White Sugar

0.5 kg Citric acid

Guidelines for Making Vegan Gummi Candy

Premix

Carrageenan and white granulated sugar are first combined in formula at a ratio of 1:4, and 35 kg of water is then added for swelling for around 30 minutes. (White granulated sugar must be finely milled in order to fully combine with carrageenan.)

Melting Sugar

Put 60 kg of syrup and the remaining white sugar in a jacketed pot or sugar pot, heat to around 90 degrees Celsius, and stir. To prevent lumps, stir while adding the white sugar.

Melt

Add the white sugar and carrageenan mixture, and keep heating until it boils.

Filtration

To get rid of contaminants, the sugar solution is filtered using an 80 mesh screen.

Boil Sugar

After filtering, keep cooking until the temperature reaches 106 to 107 degrees Celsius. When the dry matter reaches about 75, turn off the heat.

Acid Adjustment

When the sugar solution is just beginning to get cold, combine it with the citric acid and the corresponding quantity of water, then add it to the syrup along with the color and flavor. Stir well.

Pour Into a Mold

Pour the sugar liquid quickly onto a cool cooling plate that has been lightly greased with vegetable oil. To maintain the sugar liquid at a specific thickness, static, and skimming the surface of the air bubbles, the plate must be flat. To prevent the “tail dragging” effect brought on by the sugar liquid cooling too quickly, the pan should be poured quickly.

Cooling

Once the sugar liquid has been added to the pan, let it cool naturally until it becomes a jelly-like substance.

Making Cuts and Forms

Use a hob with a properly fitted blade to chop into pieces the cooled sugar liquid.

Drying

Place the sugar cubes on a metal plate that has been lightly oiled at regular intervals, and then leave them there to dry. In order to prevent crusting on the surface and poor water distribution, the drying room’s temperature is closely regulated at 55 to 60 degrees Celsius. This is especially important at first. Place for 36 to 48 hours in the drying room.

Cooling

Remove after approximately 4 hours of drying and allow to cool to room temperature.

Packaging

The chosen sugar cubes are then packaged into final goods when they have cooled.

Product Benefits

The jelly candy manufactured with carrageenan has the following benefits over other jelly candies:

- Good taste

- High transparency

- Bright color

- Low cost

Carrageenan also offers a broad range of applications, quick solidification, quick drying, and energy savings.

Carrageenan is produced using a straightforward procedure that is appropriate for both mechanized continuous production and manual operation. The potential for development is very large.

Dos and Don’ts

- It is advised to dissolve the carrageenan-based compound jelly candy powder in water first because it is difficult to dissolve it in high sugar concentrations. Otherwise, it is simple to create “trachoma,” or tiny colloidal particles one at a time.

- Be mindful about lowering sugar content. If the reducing sugar content is too high, it is simple to fail while pouring into the mold; if the reducing sugar content is too low, the storage period is short and it is easy to change back into sand (not forming, drawing).

- Reasons why something might not develop or draw:

- Potential Cause

The likelihood that the colloid will be destroyed increases with the length of time. With the exception of pouring jelly sweets, it can usually end at 107 degrees.

- Moisture Content Is Too Low

The modest amount of water introduced at the beginning prevents the colloid from dissolving completely. It is advised to pre-swell the colloid with water (not absolutely necessary). Avoid adding too little water; roughly 30% is advised. There is not enough water left in the colloid at the conclusion of cooking for it to gel. This does not happen frequently.

- The Environment Becomes Acidic Due to The Acid Syrup

With the exception of pectin, acidity can quickly dissolve colloids at high temperatures, leaving insufficient colloid for gel formation. Acid should be added in the very last step, especially just before pouring the mold. Additionally, the acid must first be dissolved in water before being added, and the mixture must be swiftly agitated after addition. Sodium citrate (potassium) can be added to the syrup to regulate the pH level. If the candy isn’t sour jelly, you can add extra, like 0.1 to 0.4 percent; if it is, add 0.08 to 0.2 percent.

- Low Colloid Content

It does not happen often. In general, a modest amount of colloid will result in a taste that is a little bit delicate. Wire drawing will occur after drying if the temperature is too high or the drying period is too long.

In the end, these tasty gummy treats have demonstrated that they are a delicacy that individuals of all ages and diets can enjoy. They’re also a wonderful way to discover new substances and the science behind them. You might never look at your favorite candy recipe the same way again after learning how to make and shape vegan gummies as opposed to gelatin versions.

When used as a substitute for gelatin in vegan gummy candies, carrageenan offers a number of advantages. One benefit is that it is entirely natural, so there won’t be any lumps or irregularities in the texture of your candy. More crucially, compared to gelatin, it is far more open about where it comes from. Carrageenan comes from seaweed, whereas gelatin is made from animal byproducts. When flavor and source materials are taken into account, there is really no way to compare the two.

One-Stop Solution Manufacturer of Gummy Making Machine

One-Stop Solution Manufacturer of Gummy Making Machine