Gummy Production Line

One-Stop Solution on Gummy Making Machine

Cart

KOSBEST gummy Making Machine

KOSBEST has over 10 years of experience in the design and manufacturing of commercial Gummy Making Machine.

All our machines are completely in line with European and American food and pharmaceutical machinery standard. they are used to produce different functional gummy candy.

New change of gummy manufacturing market

Gummies are a popular treat product among consumers. in recent years, some smart manufacturers by adding different active ingredients to the formula for making different functions and effects gummies, such as vitamins, CBD gummies etc.

This innovation way has made the gummies getting more popular as a functional food supplement not only a nice treat, which also means new opportunities for traditional candy manufacturers and the health industry.

What is Gummy Making Machine

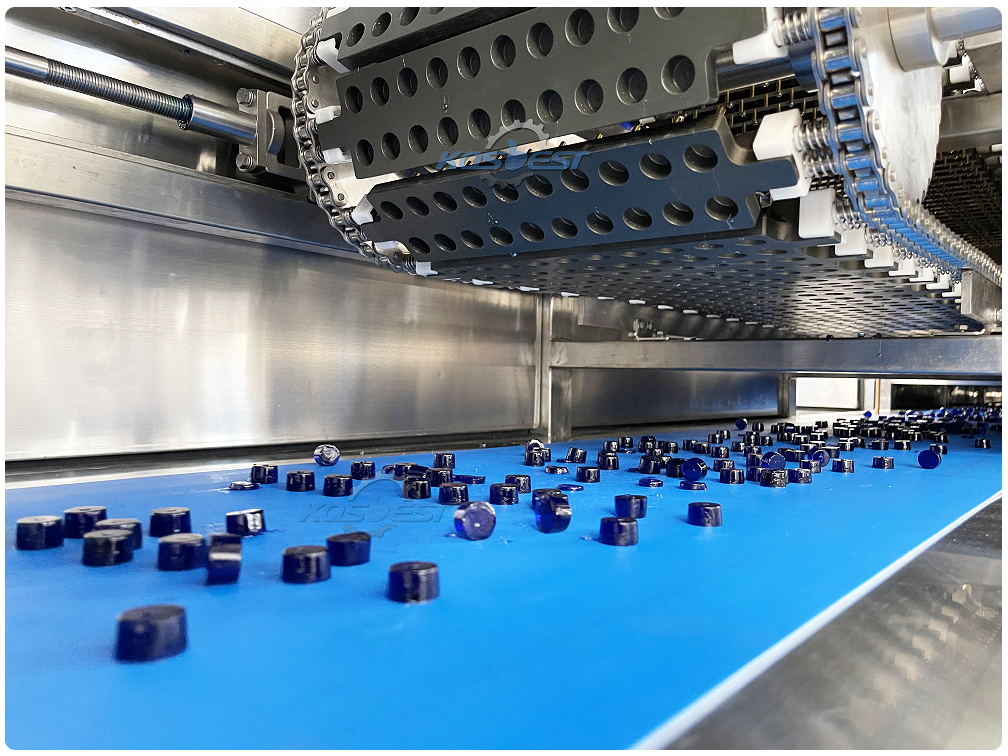

KOSBEST Gummy Making Machines are widely used for manufacture of different colors, sizes and shapes gummy candy. the basic gummy manufacturing process of them is same. just according to the difference in formula and process, some equipped machines of the gummy production line will be different.

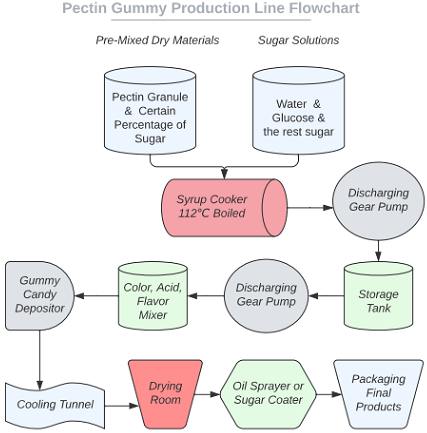

According to what type of gel ingredients are used to make gummies, KOSBEST gummy making machine can be roughly divided into two production lines, one is pectin gummy production line, one is gelatin gummy production line. then according different batch size, they are divided into GY40, GY80, GY150, GY300, GY600 and GY800 from small production to large production.

Fast Online Design Solution & Quotation For Small Scale Gummy Production Line

Small Scale Gummy Production Equipment

Large Scale Gummy Production Equipment

KOSBEST®️ Gummy Making Machine

Why KOSBEST Gummy Making Machine

KOSBEST, as a trusted Commercial Gummy Making Machine Manufacturer. the reason among the many competitors that enables buyers to choose us, offers exactly this: an extremely precise system, that ensures each gummy bear contains the exactly amount of activity ingredient you want.

Gummy Production Line Solution Expert – KOSBEST

• Over 10 years of experience in gummy equipment manufacturing.

• Long-term cooperation with 3 large Euro & USA engineering companies. in line with international manufacturing standard.

• Flexible machine design solution ability

• Skilled team technical support.

ShowRoom in USA

The KOSBEST showroom is designed to provide customers with on-site expert guidance.

Benif:

♦ Better understand how machine works.

♦ Find best machine solution to your production.

♦ Test your product possibilities.

♦ Know the latest gummies market trend.

In-Stock Machine

In order to ensure on-time delivery of all orders, we regularly premade hot-sale machines in stock.

Specs of in-stock machine:

• Production capacity: 50-80kg/h.

• Power: 220V/3hp/60hz.

• Application: Pectin/Gelatin gel-based gummies.

Process Time: 3-5 days

Know more details, chat us!

Certification

All our technological innovations are based on quality and safety.

Our Machine Verified by:

♦ ISO Certification

♦ GMP certification

♦ CE Certification

Advantages of Machine

Modular Design

KOSBEST gummy candy machine line used modular design. each part is independent, with only a few connecting pipes and cables, which greatly reduces the time of disassembly and assembly.

The whole assembly process as simple as building blocks, comepletely different from traditional candy machine struction.

High Precision and High Quality Teflon Gummy Candy Molds Design

The precision and quality of the gummy candy molds is a main part which directly affects the end quality of gummy candy. considering this point, the aluminum alloy materials, coating processing and machining accuracy of our gummy candy molds are made according to the high standards.

A normal gummy candy mold may produce white powder after being twice used and cleaned. But our Teflon molds solve this problem.

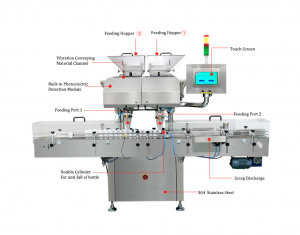

High Precision Output Controlled System

For a gummy candy manufacturer, what is the most important?

Reduce Waste.

KOSBEST’s PLC control system and dosing control system make it easier for you to control your production as your want.

UL/CSA Electrical Safety Standard

The electrical of our gummy bear machines is made according to the UL or CSA standard.

We have to ensure your full gummy manufacturing process is undering safe!

Easy Cleaning Way & Long Service Life

All machine parts are made of 304 or 316 stainless steel. the welding and polishing processing all according to pharmaceutical machinery standard.

You can directly use water or other cleaning agent to clean them.

They are no have any hard-to-reach areas for cleaning and no spot welding. the equipment will not rust after decades of use.

How Work With Gummy Making Machine

KOSBEST Gummy Making Machine is an automatic continuous production line for producing different shape and size gummies. two dosing system design allow you to make single or double color of gummies. Max batch size can up to 240,000 or more gummies per hour. you can choose to use pectin, gelatin, carrageenan, agar etc gel powder to making different gummies. below is a flow chart of a pectin gummy production for you refer:

ULTIMATE GUIDE

How to Built Your Gummy Production Line

If You are a New Start Up Factory in Gummy Candy Industry. Planning to Find a Good Gummy Production Line Manufacturer and Want to Know the Newest Market Trends on Gummies Business. You Already be in the Right Place.

Write Down your Email Where Should We Sent to You

FAQ

We take pride in the quality of our products and offer the best in terms of performance. To keep this quality level high, it is important that users properly maintain the and to maximize the longevity and safety of using it.

This need to be cleaned regularly to ensure the gummies they produce are always perfect. Here are some helpful tips for cleaning your gummy making machines.

1: Use a soft cloth and warm water to wipe the exterior of your machine when it is cool. This will remove any dust that may have accumulated during use and help keep your gummy making machine looking great.

2: If gummies build up on the blades, simply soak them in a solution of warm water and baking soda to remove the gumminess.

3: The rollers that push the gummy mix through the machine should also be taken out periodically and cleaned with warm water or a mild soap or detergent to ensure that they do not accumulate gumminess from the batches produced.

In addition, it is recommended that you periodically replace parts such as rubber mixing blades and heat resistors; this will not only ensure peak performance for the machine but will allow for more flexibility and better texture for gummies.

Jelly making machine is a production equipment that can be used to produce all kinds of gummies, candies, marshmallows and so on.

We’ll start with ingredients. Some materials are too hard for your machine, and some can cause damage to it. If you get a machine that’s made of these materials, you might be able to use it for a few months, but it will stop working soon after. You could end up spending more money on parts than you would have spent on a better machine in the first place.

Before making a purchase, take time to examine the quality control measures. Ensure that that it has rubber-like gaskets located along the edges of its base and lid. This not only prevents leaks but also helps maintain the temperature at which works. The gaskets should be made from food-grade rubber that is elastic enough to mold itself around ingredients without cracking or ripping them apart. If you notice any cracks or tears in the gasket material, do not purchase this machine! Cracks or tears making.

In addition to checking the material, you should also make sure your machine is made in China or Japan. These countries have strict standards for testing food-related products, so they’re less likely to damage your gummy making process or hurt your health. You can recognize Chinese or Japanese products by looking at the label. If it says something like “Made in Japan” or “Made in China,” then you know it was made by a reputable brand that knows what they’re doing.

One-Stop Solution Manufacturer of Gummy Making Machine

One-Stop Solution Manufacturer of Gummy Making Machine